World Premier Packaging Co., Ltd.

Measurement of the quality of corrugated boxes

Measurement of the quality of corrugated boxes

Measurement of the quality of corrugated boxes

Measurement of the quality of corrugated boxes can be measured by

1. Bursting Strength is the ability of paper to resist pressure acting on the paper until the paper is eventually forced to stretch and burst. Therefore, bursting strength is a box quality required for products that cause pressure from the inside to the outside of the box in a small area, such as products in the form of pellets, flakes, lumps, and lines. In addition, it is a quality related to the ability to support the weight of the product that is weighed down on the bottom wall of the box when moved by people.

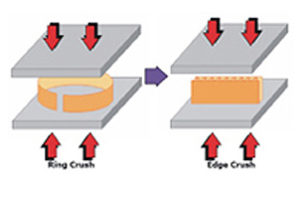

2. Ring Crush Resistance (Ring Crush or Ring Crush Test) The ability of paper to resist pressure in the same plane as the paper, which presses until the paper breaks and collapses. The resistance of the ring crush of paper in the machine direction (Ring Crush CD) is a paper quality that is directly related to the ability to resist compression. Box (Box Compression Strength/Test) is a quality that is necessary for storing, moving and transporting goods in corrugated boxes. Products that cannot withstand pressure or have little resistance to pressure must use boxes that can withstand high pressure depending on the conditions of use. Boxes that can withstand high pressure must also consist of paper that has high resistance to ring crush at the desired level.

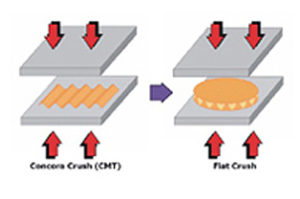

Corrugated Crush Resistance (Concora Crush Test) of Paper

Product cost is a major factor that is important for businesses. Choosing packaging made from corrugated paper can help entrepreneurs reduce costs because corrugated paper is cheaper than using packaging made from other materials such as plastic boxes or wooden crates, etc.

4. Environmental benefits

It is the ability of the paper to resist the pressure on the corrugation until the corrugation collapses until it is flat. This quality is directly related to the resistance to the corrugation pressure of the corrugated sheet (Flat Crush). Therefore, if you want a box that can withstand a lot of corrugation pressure, you must choose paper that has a lot of resistance to corrugation pressure as well.

Details of the important qualities of box liner paper and corrugated paper of all grades and standard weights

Summary in the table below

| Paper type | Grade | Standard weight (gsm) | Min Bursting Strength (kg/cm2) | Min Ring Crush C.D. | |

|---|---|---|---|---|---|

| (kg/6 in.) | (kg/cm) | ||||

| Kraft Linerboard | |||||

| KS | 170 | 3.9 | 19.37 | 1.27 | |

| KA | |||||

| 125 | 3.5 | 13.26 | 0.87 | ||

| 150 | 4.2 | 18.35 | 1.20 | ||

| 185 | 5.1 | 22.43 | 1.47 | ||

| 230 | 6.4 | 28.55 | 1.87 | ||

| KI | |||||

| 125 | 2.6 | 10.71 | 0.70 | ||

| 150 | 3.1 | 14.28 | 0.94 | ||

| 185 | 3.8 | 17.85 | 1.17 | ||

| Paper type | Grade | Standard weight (gsm) | Min Bursting Strength (kg/cm2) | Min Ring Crush C.D. | |

| (kg/6 in.) | (kg/cm) | ||||

| Corrugating Medium | |||||

| CA | |||||

| 105 | 16.31 | 8.67 | 0.57 | ||

| 125 | 19.37 | 12.24 | 0.80 | ||

Note: The information in the table may change at any time, depending on the raw materials used to make the paper pulp and the quality of the paper of each manufacturer. The information shown here is only preliminary information to show that KA grade paper is the toughest, followed by KS and KI, whereby the toughness of the paper is related to the standard weight of the paper as well.

If interested, please contact us for more details at

Line ID : @worldpremier218_wp

Happy to give advice and recommendations to suit customer use.

Follow good knowledge at www.กล่องลูกฟูก.com